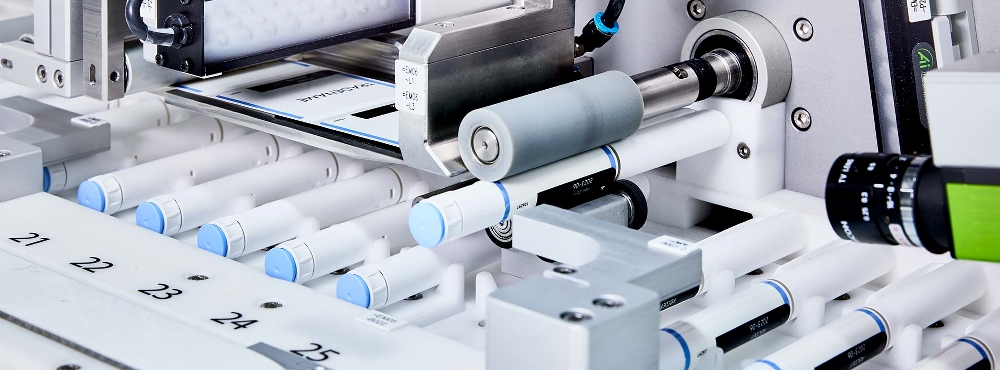

how we built a made to measure pen labelling machine in our workshop

A 3-month building pen labelling solution

with tolerance of ±1.0mm label placement for rotational orientation

The machine is designed as an off-line unit, for applying labels to pens, including label presence control, reject of

re-workable pens.

Built with focus on :

- Gentle product handling.

- Secure and easy line clearance.

- Easy maintenance and service.

- User-friendly HMI.

- Can be operated only by one operator.

- Precision in printing and labelling.

- Good operation and service ergonomics.

- High level of control functions.

- Easy cleaning, materials resistant to purified water and ethanol.

Tolerances :

- ±1.0mm Label Placement on height of device

- ±1.0mm Label Placement for rotational orientation

- ±0.25mm Label Skew

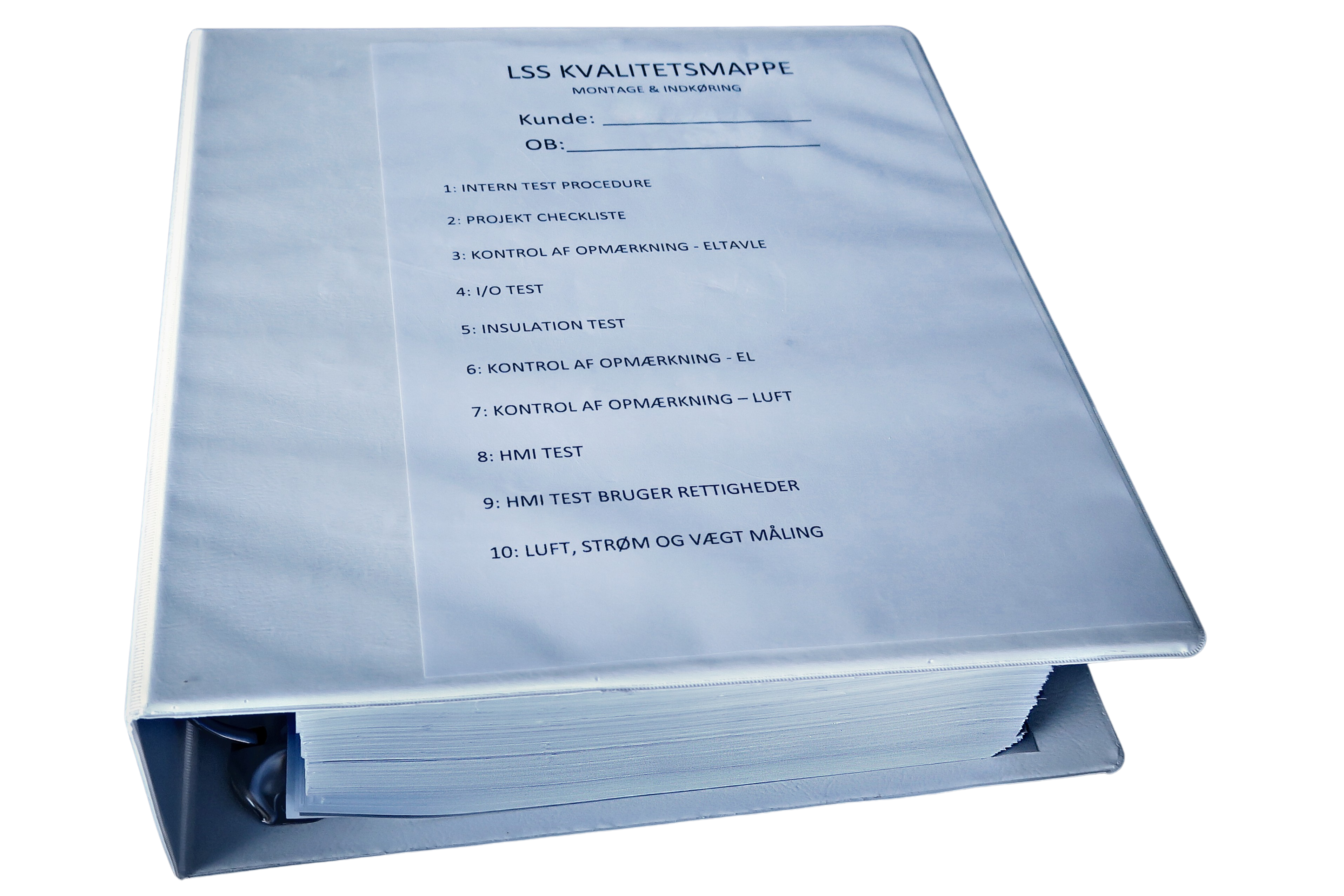

How we use our quality manual to make sure the machine is ready on time in the right quality

When we deliver our projects, quality and safety are of the utmost importance for us.

Therefore, when preparing our labelling machines for FAT, we used our quality manual to ensure the machine is checked and ready as expected. Our quality manual contains the following checks:

- Internal test procedure

- Project check list

- Control of marking in electrical cabinet

- I/O Test

- Insulation test

- Control of marking – electrical

- Control of marking – air

- HMI test

- HMI test, user rights

- Air, power, and weight measurement

Our labelling solutions for pharmaceutical industry

Would you like to know more about our solutions for the pharmaceutical industry?

Contact our experts