Tamper Evident

Tamper proof sealing of cartons

Improved presence verification of transparent Tamper Evident Labels

Do you experience the following challenges :

- Continuous manual adjustment of sensor settings, with the risk of manual error and false confidence

- False positive (products without label are approved)

- False Negative (products with correct label are rejected)

- Validation of setup has proven difficult

- Calibration of sensor for different carton sizes or artwork is difficult

If you can recognize some of the above points, we can help solve your challenges.

Together with UPM Raflatac, we have developed a solution combining label material and a sensor to eliminate all the above challenges. The solution can easily be retrofitted onto both existing and new production lines.

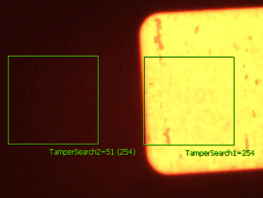

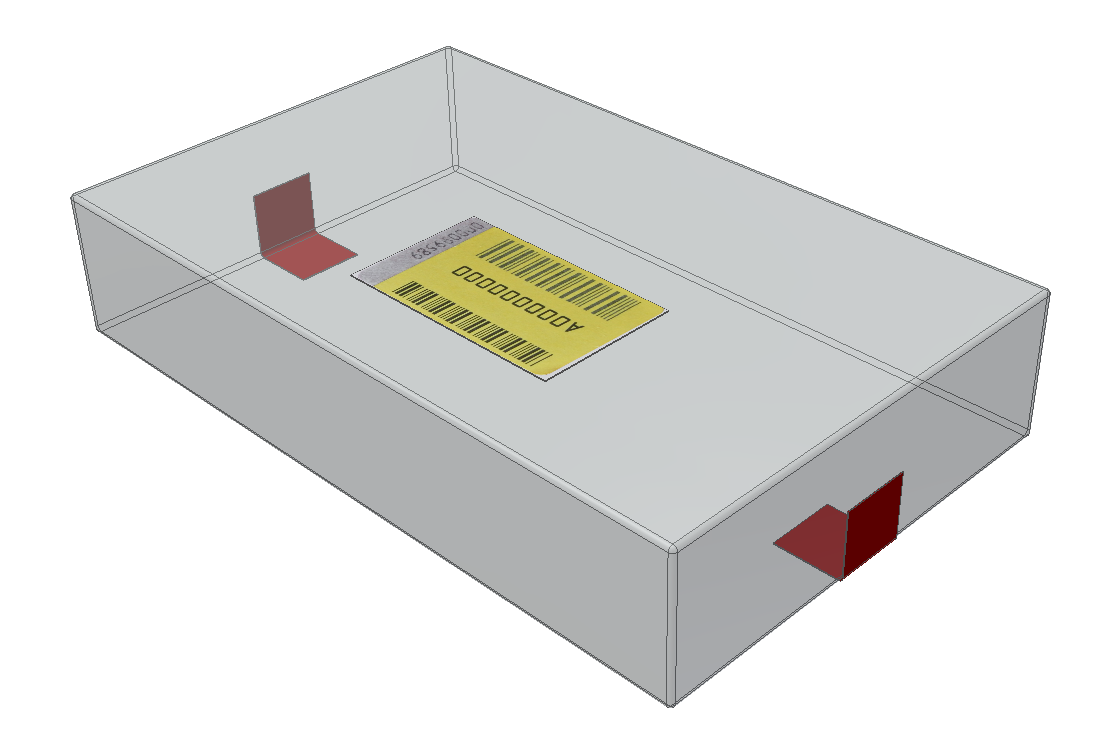

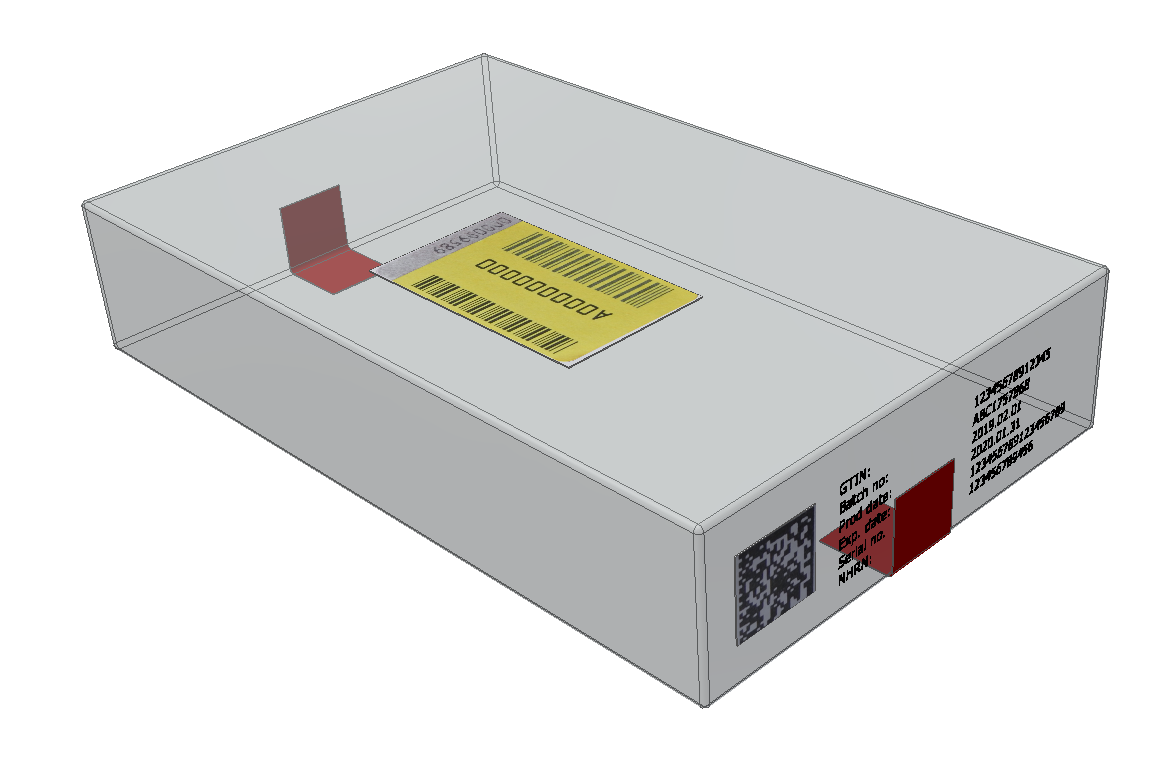

The picture shows how clear the sensor can verify presence of a label on the carton

When testing in our test station, the sensor gives a score for the area where the label is detected, a score is also given in the area where no label is detected. The difference of the scores can be used for validation of how reliable the label presence verification is. In this case the score where label is detected is 254 and the score where no label is detected is 51, which gives close to a factor 5 safety.

See the detailed video

Sign up and get access to the full video material

Receive relevant information about our solutions for the pharma industry

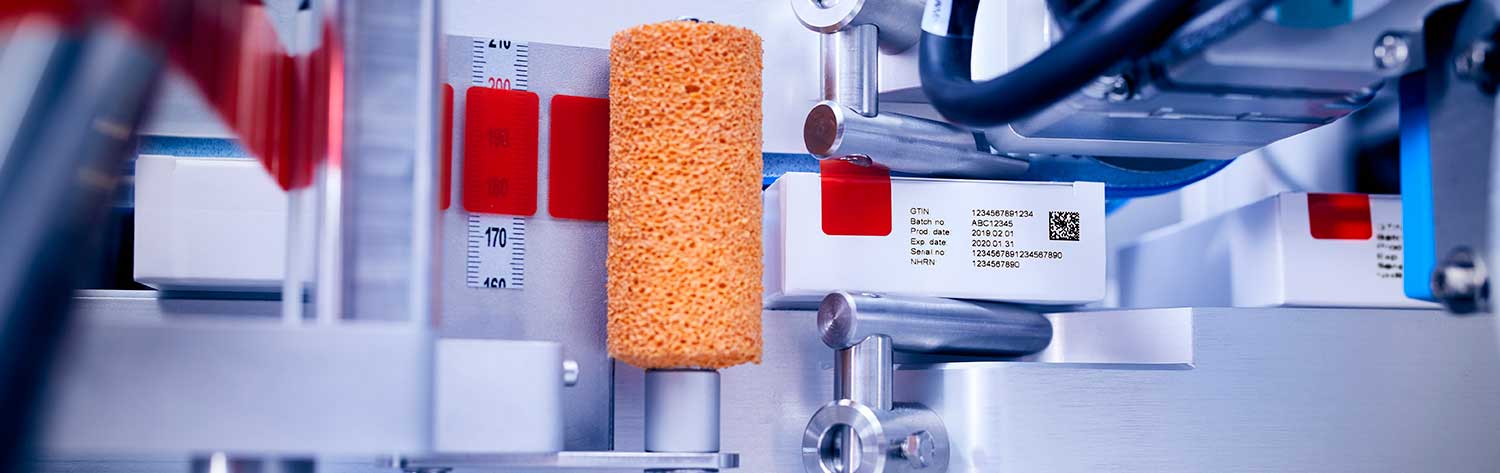

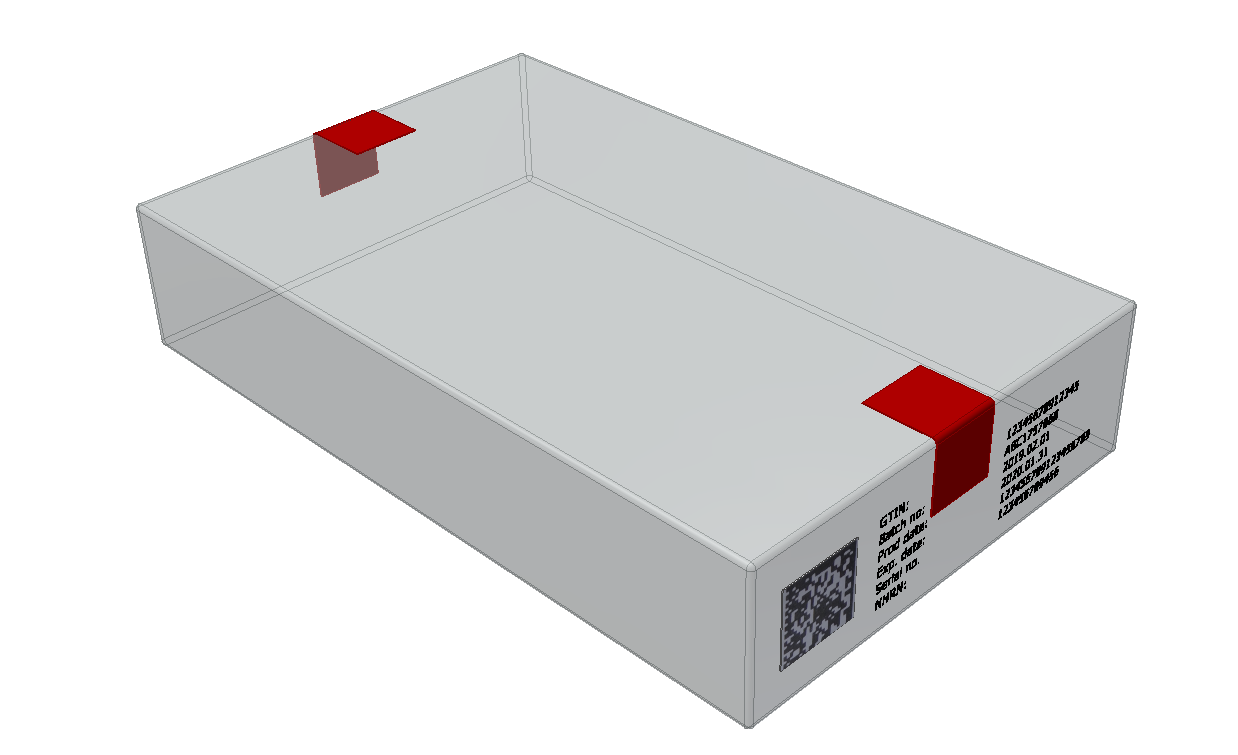

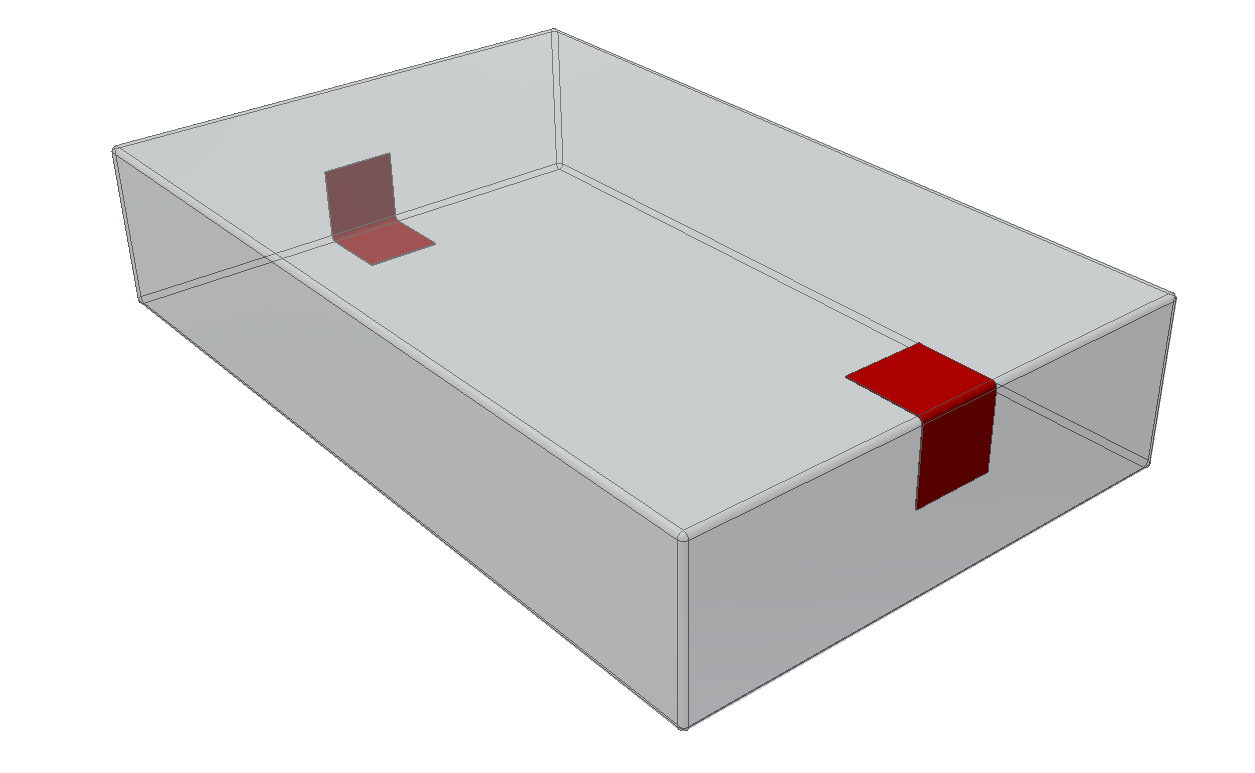

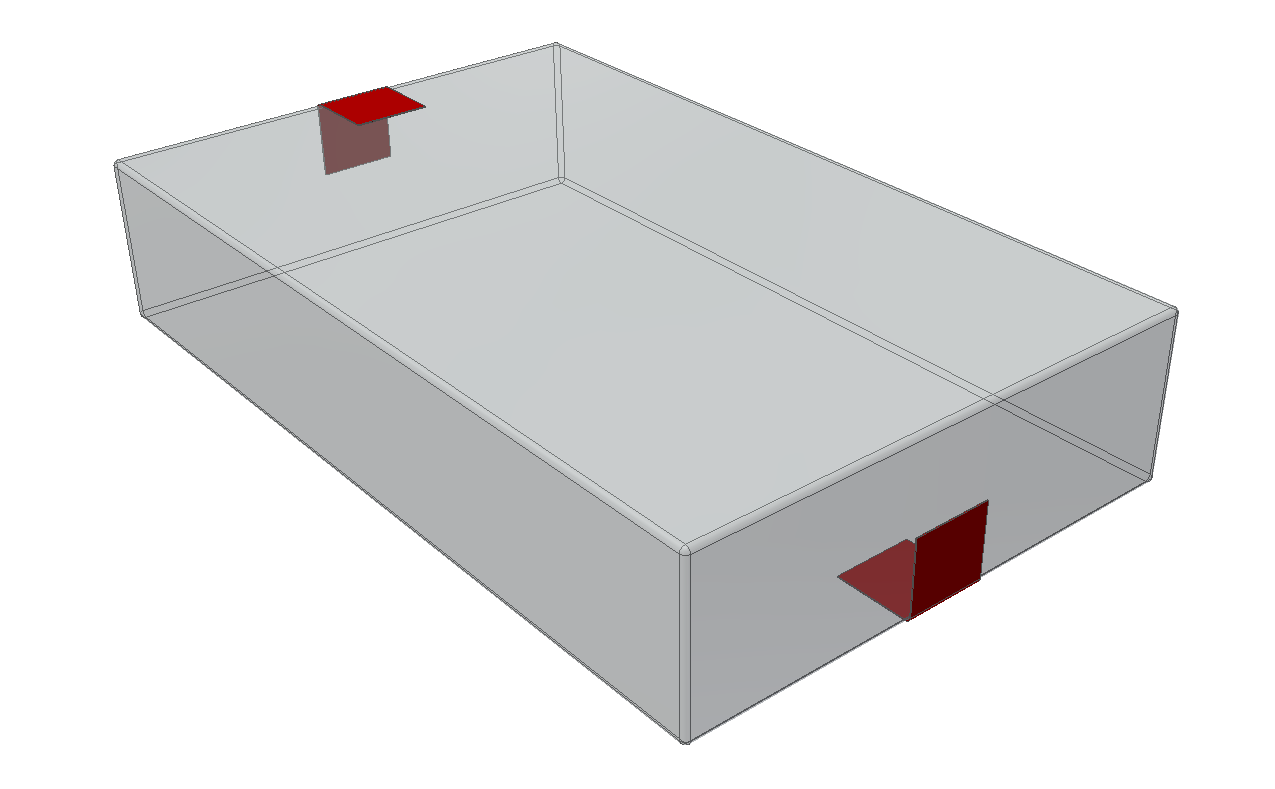

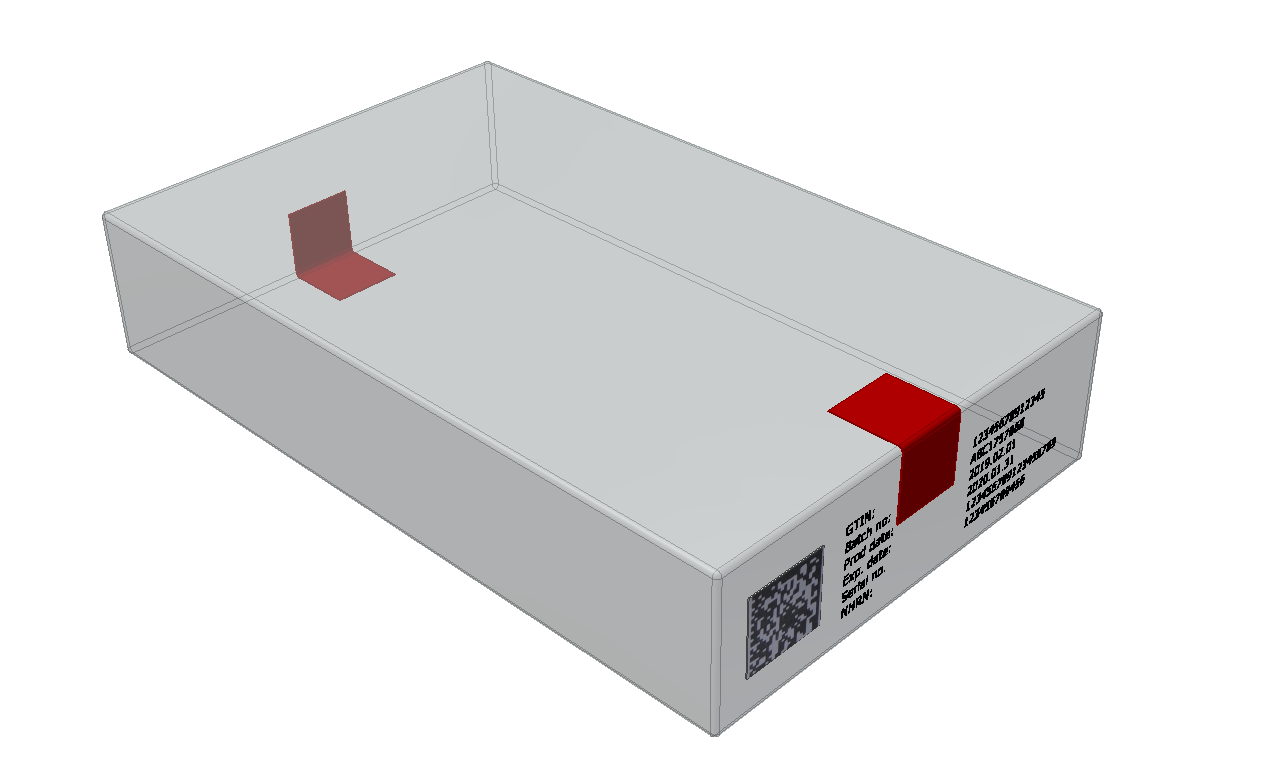

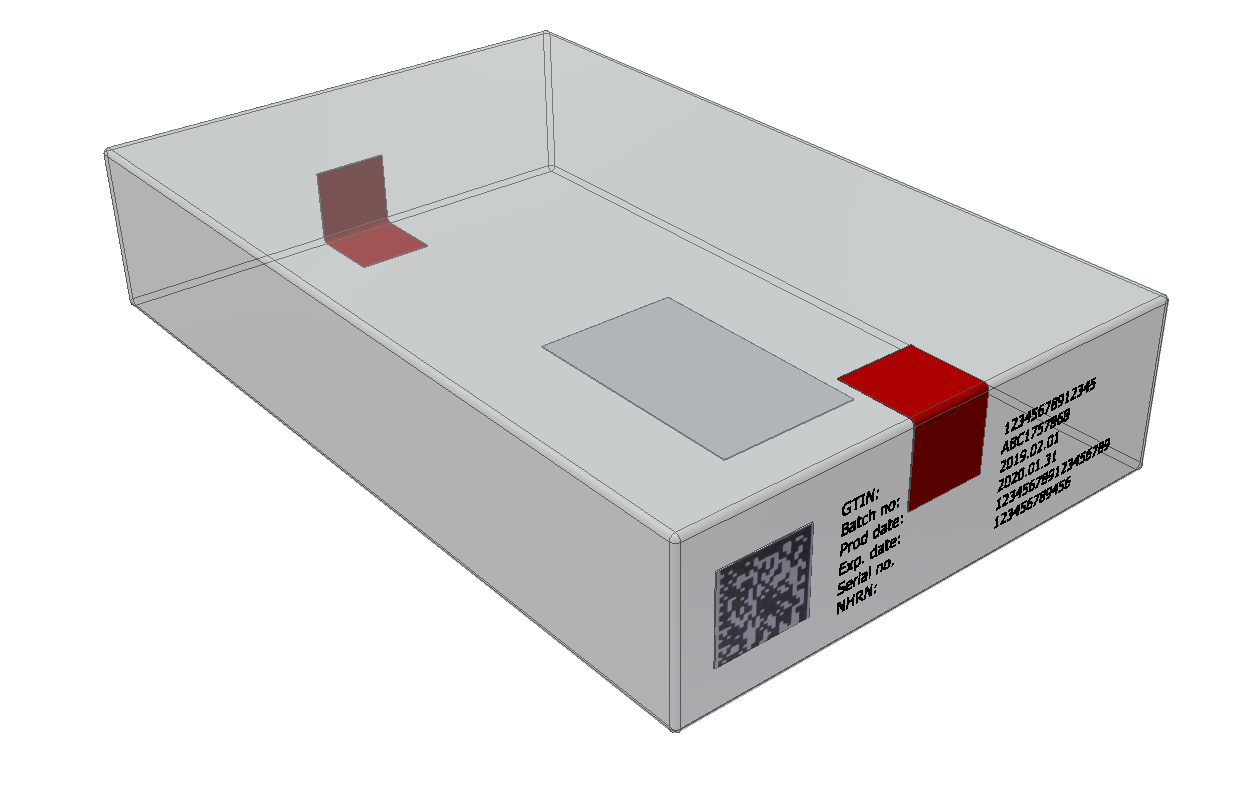

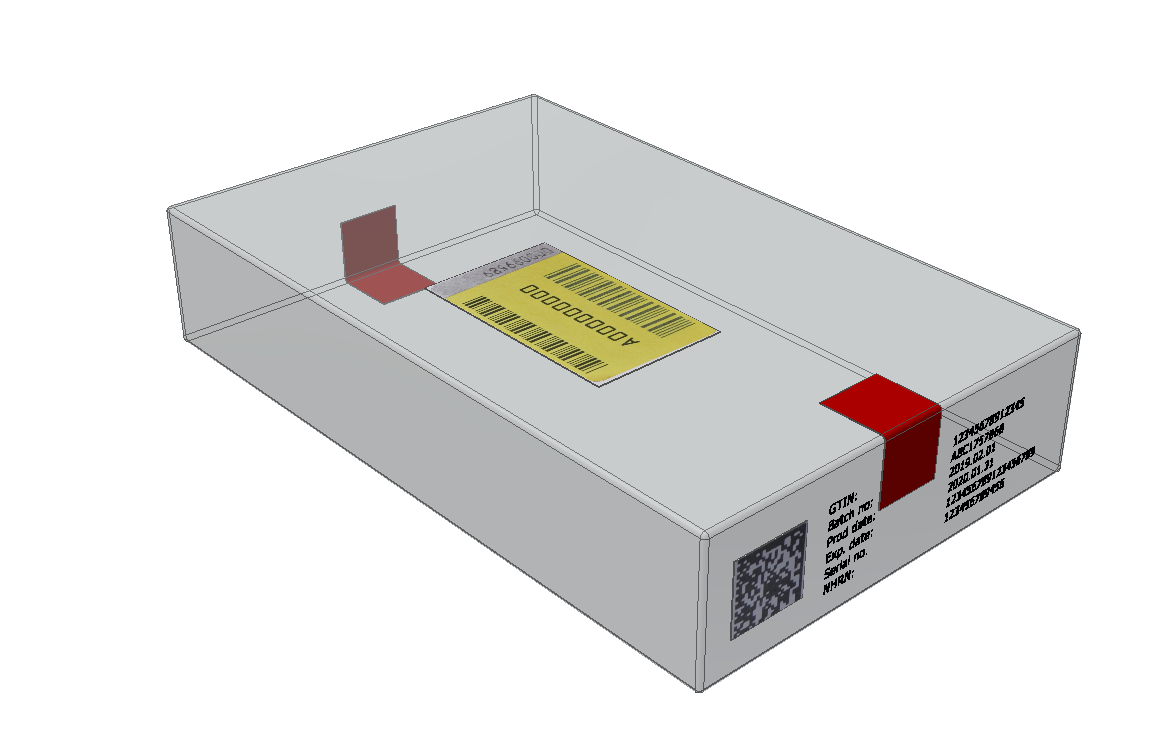

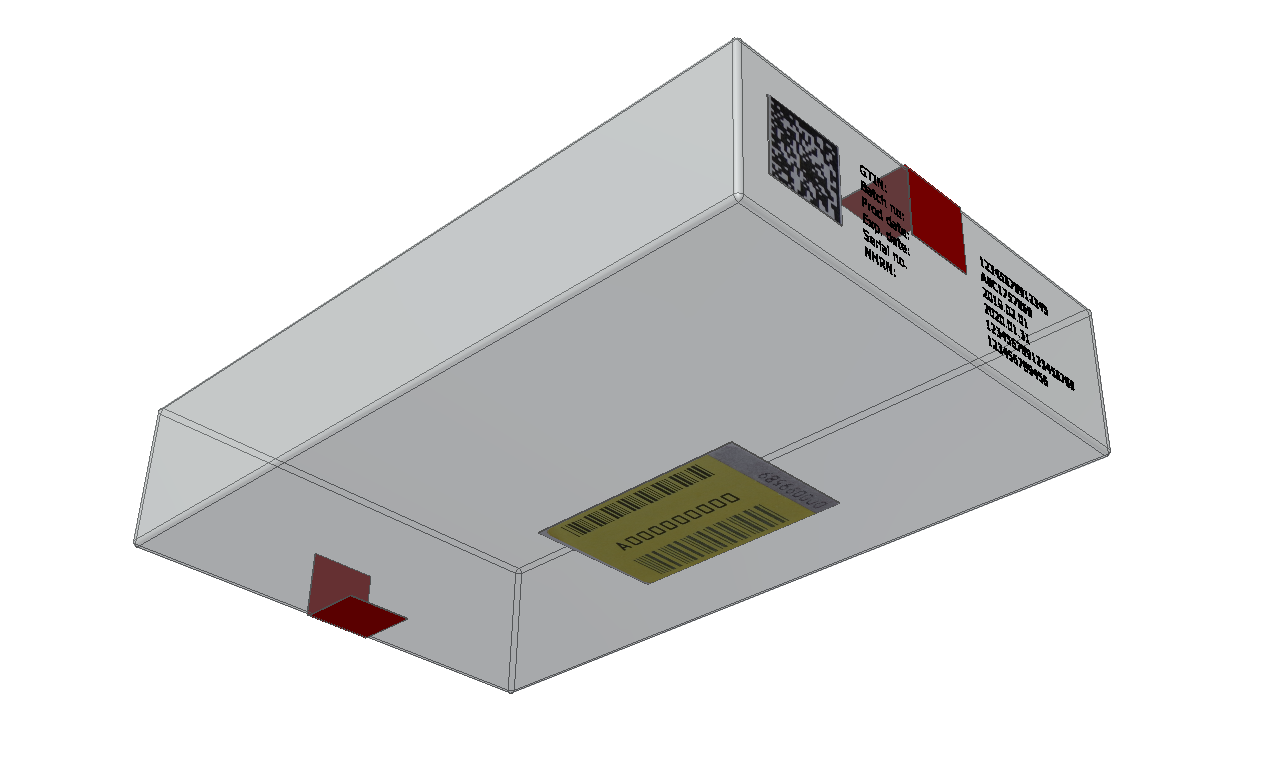

Tamper proof sealing of cartons in compliance with the FMD (European Union Falsified Medicine Directive) 2011/62/EU.

The FMD is designed to protect patients by minimising the chances of counterfeit medicines entering into the established medicines supply chain across Europe.

A part of the directive concerns a tamper evident functionality of each carton, to ensure that it has not been tampered with.

Each carton also needs to be marked with a unique 2D barcode, to be serialised.

For print of 2D barcodes for serialisation and track & trace, we can integrate printers and vision systems of all common brands.

- Adjustable for different product sizes from small to large cartons

- Both front doors can be opened for easy access to the machine

- Small foot print for easy integration

- Safe synchronisation - the machine can stop and still maintain a safe product register

- Easy label roll change

- Multi language operator panel

Our standard Tamper Evident Labeller is very flexible and easy to integrate into existing production lines and systems.

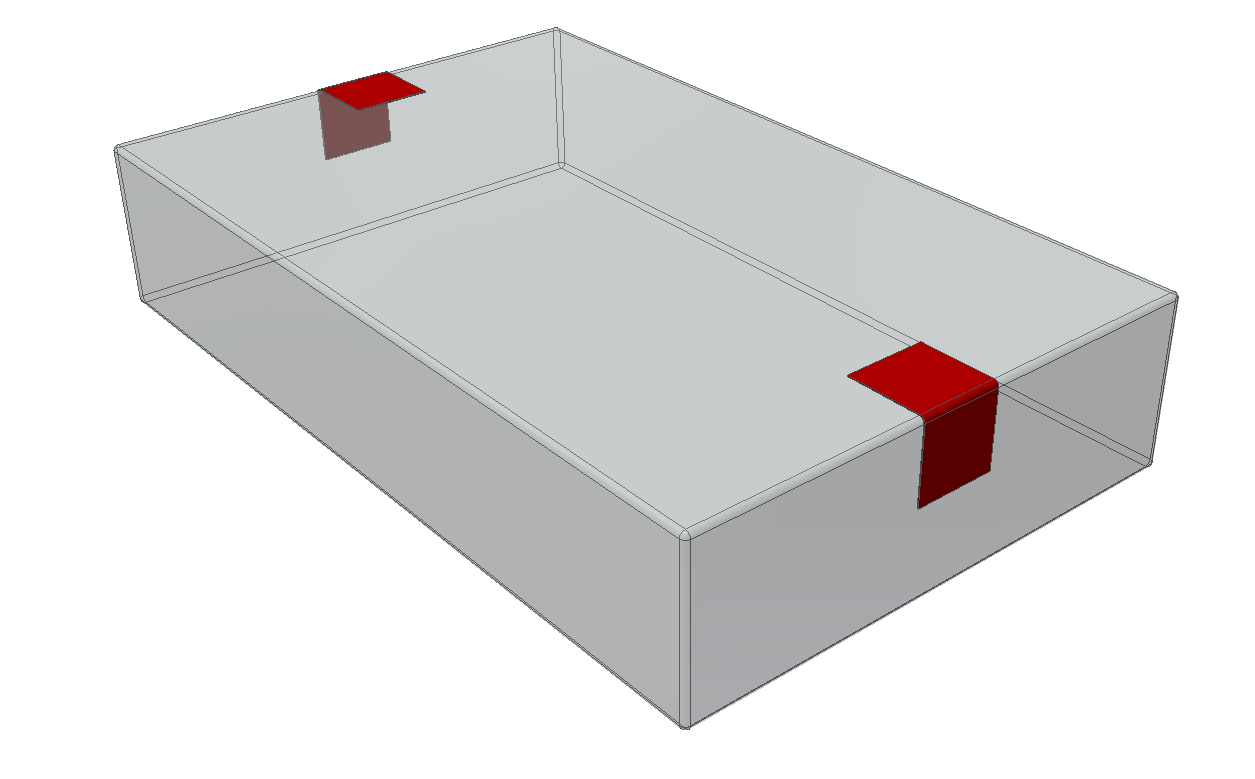

It is possible to apply one or two tamper evident labels including check in any position, including control of label on product, with an automatic reject system for non approved products.

Easy format change, even between airplane and RTE cartons.

It is possible to print serialisation and batch data with ink-jet or laser. Our Tamper Evident Labeller is prepared for easy integration of ink-jet or laser of different brands. Also vision systems of different brands can be integrated.

Specifications

Options

- Ink-jet printer or laser of several brands can be integrated

- In-line or off-line execution

- Vision systems of several brands can be integrated

- Swing out function of dispensers for easy maintenance

- Audit trail, access control, recipe management

- Apply of extra price sticker / vignette label

Other solutions for pharmaceutical products

If you would like to know more about labelling solutions for the pharmaceutical industry please contact our pharma labelling experts

- Søren Andersen

![Søren Andersen]()

- Jan Vinther

![Jan Vinther]()