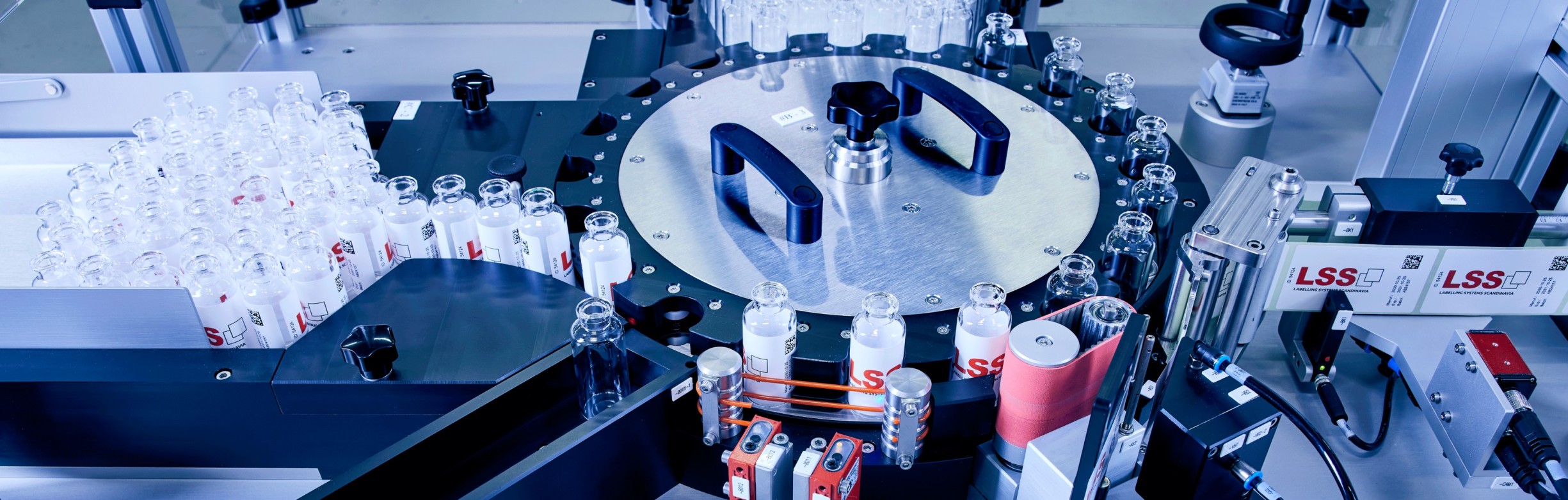

Vial and ampoule labeling machine

Automatic labeling solutions for vials and ampoules

Our product program for labelling and marking of vials, ampoules and small cylindrical products, range from simple off-line units, to integrated in-line labelling solutions with a capacity up to 400 products per minute.

Our solutions are designed with primary focus on user friendliness and maximum reliability, when it comes to secure and gentle handling of vials.

We understand that the use of a vial labeling machine within the pharmaceutical industry is not just the period of time when the machine is running, but equally important is the time spend on batch start/stop, format changes, line clearance, cleaning, maintenance and service.

Regardless of you being an operator or a technician, you will find “special” features designed to ease the interaction with our machine.

See the detailed video

Sign up and get access to the full version of the vial labelling video.

And also video of other labelling solutions we have made for the pharmaceutical industry

Customised labeling solutions built from standardised modules

All our vial labeling solutions are unique but we never start from scratch. We have a long history in the pharmaceutical industry and a long list of proven concepts that have already stood the test of time.

Our vial and ampoule labeling machines are made of standardised modules which are combined to create the exact labelling solution you need. This way you don’t have to choose between an expensive fully customised solution and a standardised machine.

Instead, you get the best of both worlds with a module-based vial and ampoule labeling system designed to meet your requirements and ensure a short time to market.

Labelling solutions for vials and ampoules

Small vial/ampoule labelling machine

- Compact stand-alone labelling unit for secure and gentle labelling of ampoules, vials and small bottles.

- Capacity up to 150 vials / ampoules per minute.

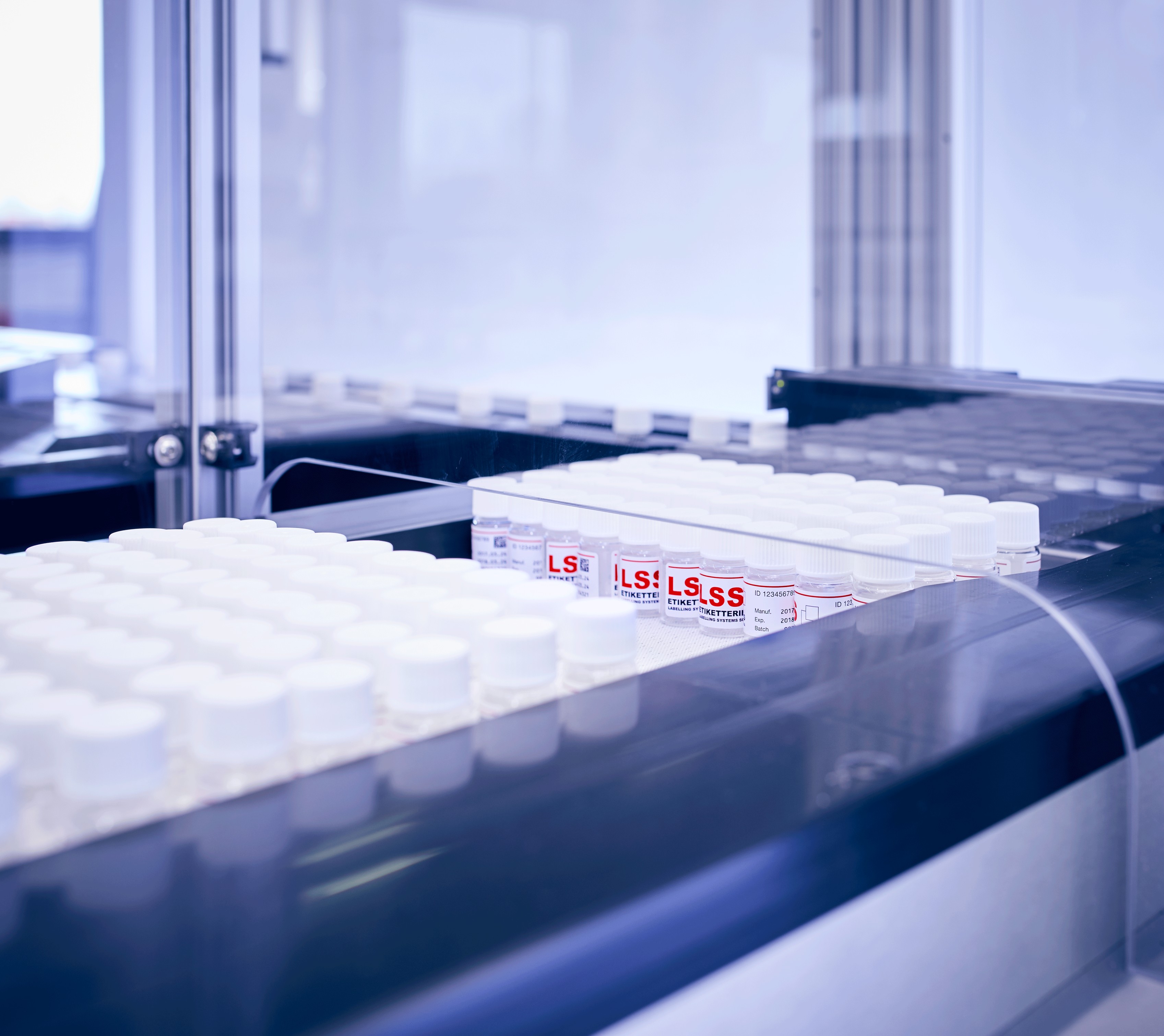

- Product in-feed from trays products entering the star wheel and back into trays. Including device for easy handling of products at in- and out-feed of the labelling unit.

- It will be possible to print variable and unique data for each vial / ampoule before apply of the lable onto the vial/ampoule/bottle. A vision system can be integrated in order to control print and detect correct label placement.

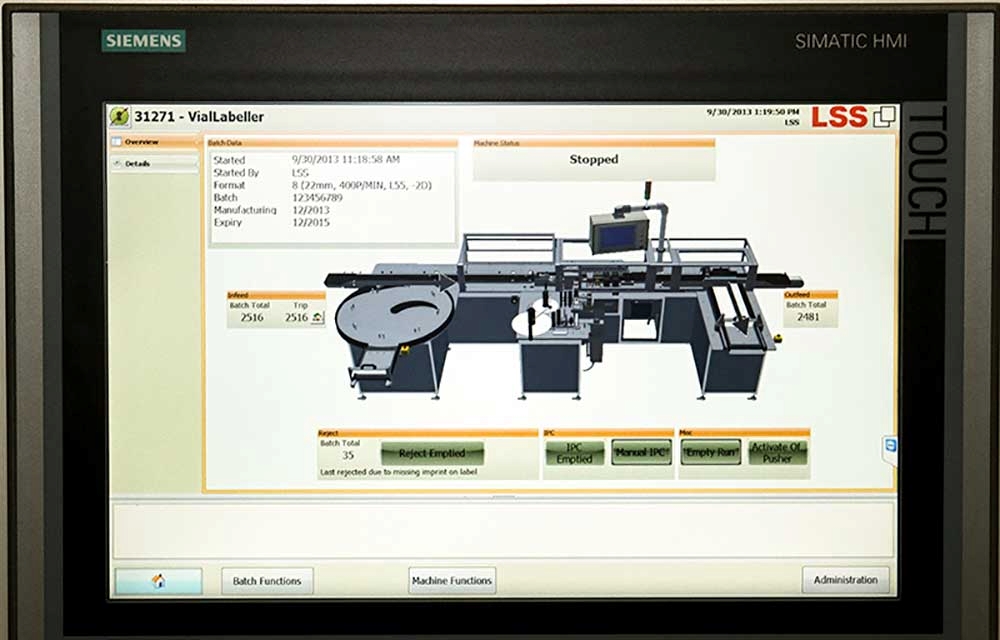

- The labelling unit is operator friendly, the HMI is very intuitive and provides the operator with full visibility of the status for the machine.

Automatic vial labelling with Vision

- We have designed this standard vial labeller for secure and gentle handling of vials and small bottles.

- Capacity up to 300 vials per minute.

- Product infeed from tray via turn table and conveyor or in-line from upstream machine via conveyor.

- The vial labeller can be delivered both as an off-line and an in-line unit.

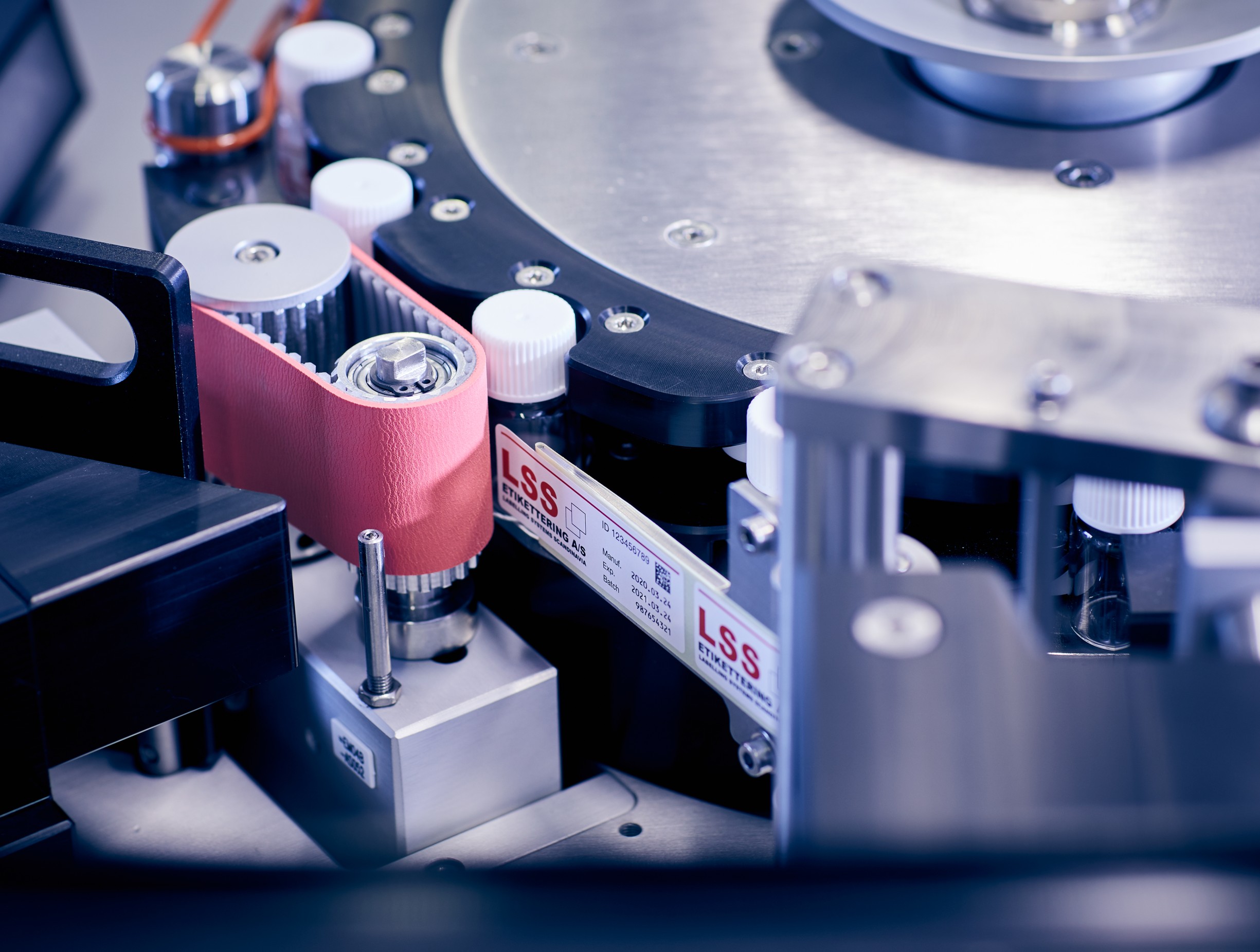

- A thermal transfer printer is integrated to print variable information onto the label.

- Vision inspection of print before apply of label onto vials and vision inspection of label on product and placement of the label, only approved vials are allowed to leave the index wheel.

- Very user friendly HMI.

Labelling of vials - capacity 400 p/min.

- Product infeed from tray via turn table and conveyor or inline from upstream machine via conveyor. Separation of products done by worm screw. Labelling of products in roller conveyor.

- This machine is built for both off-line and in-line use. When used in-line the products continues on conveyor for the subsequent equipment. When used off-line the integrated out-feed module is used, where the labelled products are lead back into trays.

- Label marking is done by laser.

- Vision inspection on label. Vision control of label presence on product, including product reject.

- Easy overview of the machine from the HMI.

Specifications

Options

- Format parts for multiple product sizes

- Print on label with thermal transfer printer or laser

- In-line and/or off-line execution

- Automatic height adjustment of complete machine

- Vision inspection of label before application including reject of non approved labels

- Vision inspection of vial after labelling including reject of non approved vials

Automatic vial and ampoule labeling solutions that meet your requirements

Before we build a vial or ampoule labeling machine we put a lot of work into the clarification and design phase where we layout and sketch the solution in close cooperation with you. We go through your user requirement specification (URS), pick the relevant modules for the requirements and show you how they can be combined into a final vial or ampoule labelling machine.

When we have agreed on the design we order the parts for the modules and assemble your vial or ampoule labelling machine by putting together our already proven modules into a customised labelling solution.

Together we make a factory assessment test (FAT), where you get to try out your new labeling machine in real life.

When it’s time we can aid you through the entire installation process of your new labelling machine and support you through the site acceptance test (SAT) as well. Just like we can provide you with all the validation documents you need too.

In other words, we are here to help you through the entire process. From design and assembly to installation and documentation.

We know your time to market is crucial…

… that’s why we assemble your customised labelling solution from proven standardised modules to ensure you a reliable vial or ampoule labelling machine instead of starting from scratch every time.

The five considerations you need to make before purchasing a labelling solution

Extensive inspection of every label and vial or ampoule

Correct labelling is crucial to ensure a quality product and to help clinicians and patients accurately administer treatments. That is why every vial or ampoule labelling machine is equipped with highly precise cameras and sensors that automatically check every label and vial or ampoule and reject any non-approved product.

- Automatic vision inspection of every label. Non-approved labels are discarded before application to vials or ampoules to reduce waste and enhance safety

- Automatic vision inspection of the final product after the application of the label

- Sensors register and ensure the right colour, height, directions etc.

- A visual register in the control panel that matches the labelling line 1:1

- Automatic control of misplaced vials or ampoules during labelling and for line clearance

Contact us to learn more about the inspection and control possibilities

Vial and ampoule labeling machines with intuitive controls

User-friendliness is crucial for an efficient production line. To ensure this every vial and ampoule labelling machine is equipped with an intuitive control panel (HMI). An identical visual representation of the labelling machine in the interface makes it easy to make adjustments or see where the operator needs to take action.

Easy line clearance between every vial or ampoule batch

With an increasing tendency towards vial and ampoule production in small batches, line clearance becomes more and more crucial for your overall efficiency and product safety. With an intuitive control panel and a clear view of every module in the vial and ampoule labelling machine, line clearance can be done safely, quickly and effectively. Especially because the operator is guided through every step of the process.

And if the operator needs to adjust the labelling machine to another format they are guided through every step of this process as well.

We provide service for all our vial and ampoule labelling machines

When you buy a vial or ampoule labelling machine from us you can choose to add a service agreement as well. With a service agreement, our specialised service technicians will inspect and maintain your labelling machine at an interval of your choice.

To give you a hint of how long you can expect your labelling machine to last we can say that we have produced labelling machines that have run 24/7 since 1995 – and still do.

We know the pharmaceutical industry and its requirements

At LSS we specialise in labelling solutions for the pharmaceutical industry. We know exactly which regulations you face when you want to label vials and ampoules. This ensures a faster process because we speak the same language and already know how to solve many common challenges because we’ve done so before.

We use this knowledge to build you a customised labelling solution from standardised modules.

Other solutions for pharmaceutical products

If you would like to know more about labelling solutions for the pharmaceutical industry please contact our pharma labelling experts

- Søren Andersen

![Søren Andersen]()

- Jan Vinther

![Jan Vinther]()